- Главная

- Разное

- Образование

- Спорт

- Естествознание

- Природоведение

- Религиоведение

- Французский язык

- Черчение

- Английский язык

- Астрономия

- Алгебра

- Биология

- География

- Геометрия

- Детские презентации

- Информатика

- История

- Литература

- Математика

- Музыка

- МХК

- Немецкий язык

- ОБЖ

- Обществознание

- Окружающий мир

- Педагогика

- Русский язык

- Технология

- Физика

- Философия

- Химия

- Шаблоны, фоны, картинки для презентаций

- Экология

- Экономика

Презентация, доклад на тему Aircraft fuel system- топливная система самолета

Содержание

- 1. Aircraft fuel system- топливная система самолета

- 2. Цель занятия: 1. Задачи:

- 3. An aircraft fuel system allows the crew to

- 4. Fuel is piped through fuel lines to

- 5. Переведи, объясни смыслTypically, after the selector valve—situated

- 6. Расскажи о … Each tank is vented

- 7. The fuel level indication system in the

- 8. To avoid water condensation or the fuel

- 9. Aircraft Fuel System ComponentsFuel TanksFuel Lines and FittingsFuel ValvesПереведи, перевод запиши в тетрадь

- 10. Переведи, перевод запиши в тетрадьFuel PumpsFuel FiltersFuel Heaters and Ice PreventionFuel System Indicators

- 11. Слайд 11

- 12. Домашнее задание составь пересказ по тексту:Aircraft Fuel

- 13. Домашнее задание составь пересказ по тексту:Fuel Lines

- 14. Домашнее задание составь пересказ по тексту:Fuel Lines

- 15. Домашнее задание составь пересказ по тексту:Fuel Valves

- 16. Fuel Pumps Other than aircraft with gravity-feed

- 17. Fuel Filters Two main types of fuel

- 18. Fuel Heaters and Ice Prevention Turbine

- 19. Fuel System Indicators Aircraft fuel systems utilize

- 20. Ответь на английском сегодня :Я научился …Было

- 21. Источники:http://avia.pro/plane_fuselagehttps://www.aircraftsystemstech.com/2017/05/aircraft-fuel-system-components.htmlhttps://en.wikipedia.org

Слайд 1Aircraft fuel system- топливная система самолета

Выполнил: Чернявский О.В.

Троицк, апрель 2019

Троицкий авиационный

Слайд 2Цель занятия:

1.

Задачи:

Изучение топливной системы самолета

1.

2.

3.

Изучить терминологию,

Знать предназначение рассказывать о нем на английском.

Закрепить полученный материал на

практике

Слайд 3An aircraft fuel system

allows the crew to pump, manage, and

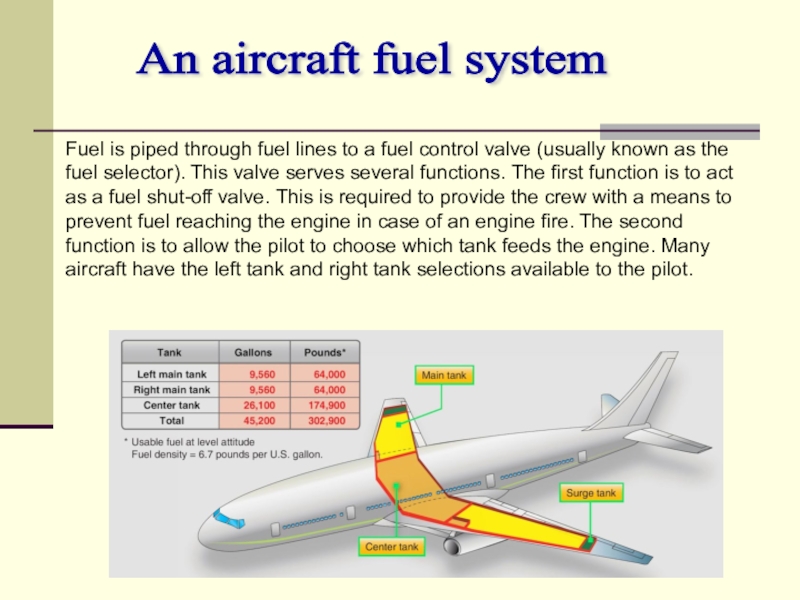

Слайд 4Fuel is piped through fuel lines to a fuel control valve

An aircraft fuel system

Слайд 5Переведи, объясни смысл

Typically, after the selector valve—situated at a low point

Some Cessna airplanes feed only from both tanks; and many have the option to feed from left, right, or both tanks. The reason to have left only and right only options is to allow pilots to balance fuel load to reduce the banking moment. In some aircraft, the shut-off function is a different valve located after the fuel selector valve.

Слайд 6Расскажи о …

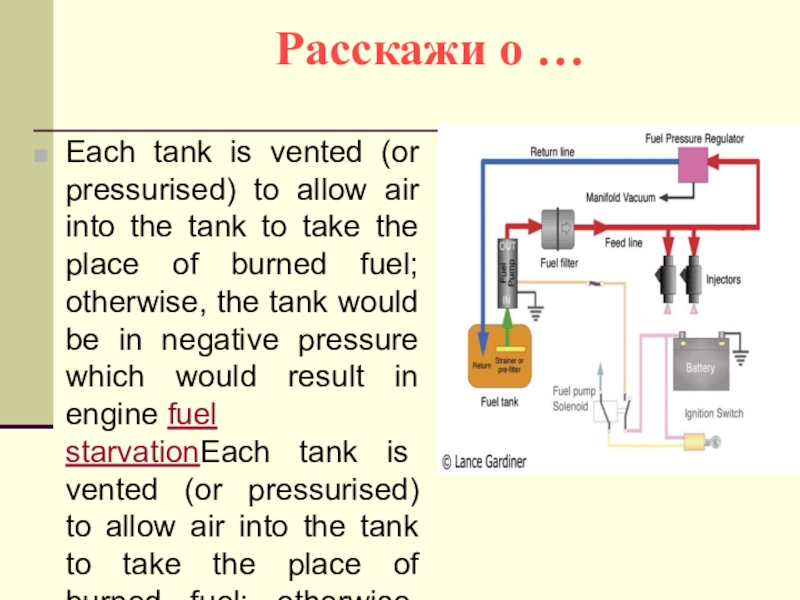

Each tank is vented (or pressurised) to allow air

Слайд 7The fuel level indication system in the simplest form is a

Переведи напиши к тексту

пять вопросов на английском

Слайд 8To avoid water condensation or the fuel itself solidifying at low

Переведи, составь пересказ

Слайд 9Aircraft Fuel System Components

Fuel Tanks

Fuel Lines and Fittings

Fuel Valves

Переведи, перевод запиши

Слайд 10Переведи, перевод запиши в тетрадь

Fuel Pumps

Fuel Filters

Fuel Heaters and Ice Prevention

Fuel

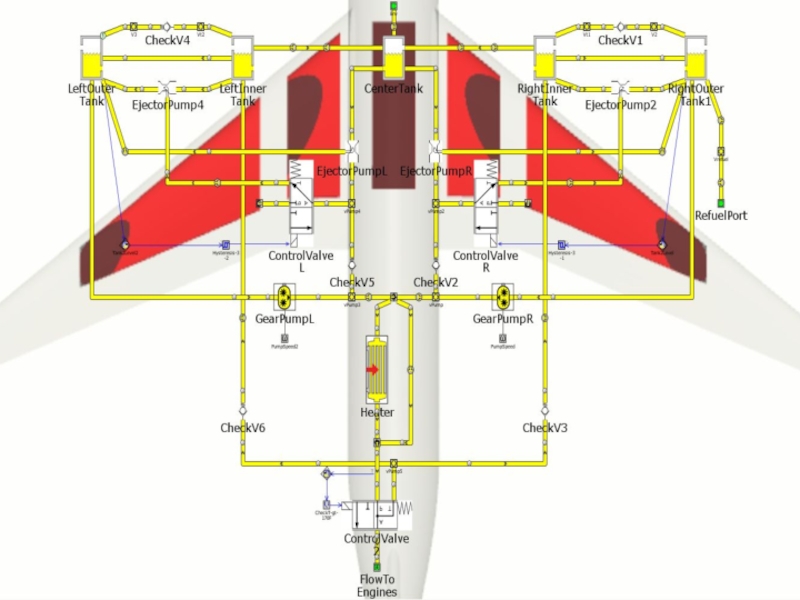

Слайд 12

Домашнее задание составь пересказ по тексту:

Aircraft Fuel System Components-To better understand

Fuel Tanks

There are three basic types of aircraft fuel tanks: rigid removable tanks, bladder tanks, and integral fuel tanks. The type of aircraft, its design and intended use, as well as the age of the aircraft determine which fuel tank is installed in an aircraft. Most tanks are constructed of noncorrosive material(s). They are typically made to be vented either through a vent cap or a vent line. Aircraft fuel tanks have a low area called a sump that is designed as a place for contaminants and water to settle. The sump is equipped with a drain valve used to remove the impurities during preflight walk-around inspection. [Figure 1] Most aircraft fuel tanks contain some sort of baffling to subdue the fuel from shifting rapidly during flight maneuvers. Use of a scupper constructed around the fuel fill opening to drain away any spilled fuel is also common.

Слайд 13

Домашнее задание составь пересказ по тексту:

Fuel Lines and Fittings

Aircraft fuel lines

Слайд 14

Домашнее задание составь пересказ по тексту:

Fuel Lines and Fittings

Technicians are cautioned

Several installation procedures for fuel hoses and rigid fuel lines exist. Hoses should be installed without twisting. The writing printed on the outside of the hose is used as a lay line to monitor fuel hose twist. Separation should be maintained between all fuel hoses and electrical wiring. Never clamp wires to a fuel line. When separation is not possible, always route the fuel line below any wiring. If a fuel leak develops, it does not drip onto the wires.Metal fuel lines and all aircraft fuel system components need to be electrically bonded and grounded to the aircraft structure. This is important because fuel flowing through the fuel system generates static electricity that must have a place to flow to ground rather than build up. Special bonded cushion clamps are used to secure rigid fuel lines in place. They are supported at intervals shown in Figure 5.

Слайд 15Домашнее задание составь пересказ по тексту:

Fuel Valves There are many fuel

Слайд 16Fuel Pumps

Other than aircraft with gravity-feed fuel systems, all aircraft have

Слайд 17Fuel Filters

Two main types of fuel cleaning device are utilized on

Слайд 18Fuel Heaters and Ice Prevention

Turbine powered aircraft operate at high

The most common types of fuel heaters are air/fuel heaters and oil/fuel heaters. An air/fuel heater uses warm compressor bleed air to heat the fuel. An oil/fuel exchanger heats the fuel with hot engine oil. This latter type is often referred to as a fuel-cooled oil cooler (FCOC).

Fuel heaters often operate intermittently as needed. A switch in the cockpit can direct the hot air or oil through the unit or block it. The flight crew uses the information supplied by the filter bypass indicating lights and fuel temperature gauge [Figure 10] to know when to heat the fuel. Fuel heaters can also be automatic. A built-in thermostatic device opens or closes a valve that permits the hot air or hot oil to flow into the unit to cool the fuel. Note that some aircraft have a hydraulic fluid cooler in one of the aircraft fuel tanks. The fluid helps warm the fuel as it cools in this type of full-time heat exchanger.

Слайд 19Fuel System Indicators

Aircraft fuel systems utilize various indicators. All systems are

Слайд 20Ответь на английском сегодня :

Я научился …

Было интересно …

Было трудно ...

Могу

Больше всего мне понравилось …